Welding Defects - How To Prevent Them!

Welding Defects - How To Prevent Them!

Blog Article

The very first thing is, this only works well with D/C Stick welding power supplies and standard air cooled, scratch start, TIG torches. You perhaps might not know this, but this basic the equipment is of the same given that the equipment put to use for welding power plants! That's right, no high end TIG welding power supplies or fancy bells and whistles. Just simple pure D/C electricity that welds most steels like carbon steel, stainless steel, and even exotic metals like copper nickel! Suggest common metal that cannot be welded this particular set-up is aluminum.

The other misunderstanding is that gardeners can buy a suitable product for $200 that mig vs tig provide quality welds. The heating must be constant and stable. The wire feed assembly must supply the filler wire at a perfect speed. Once the wire drive motor starts and stops the arc must still remain stable. Cheap products have small feed motors, small feed assembly wheels, and often use the same power source that supplies the arc. Each time the feed motor starts and stops the arc intensity varies. The wire feed on cheap machine is not smooth and constant. As soon as the wire starts and stops it gets stuck into the puddle. Cheap products are cheap as they are built with low quality parts and old machinery.

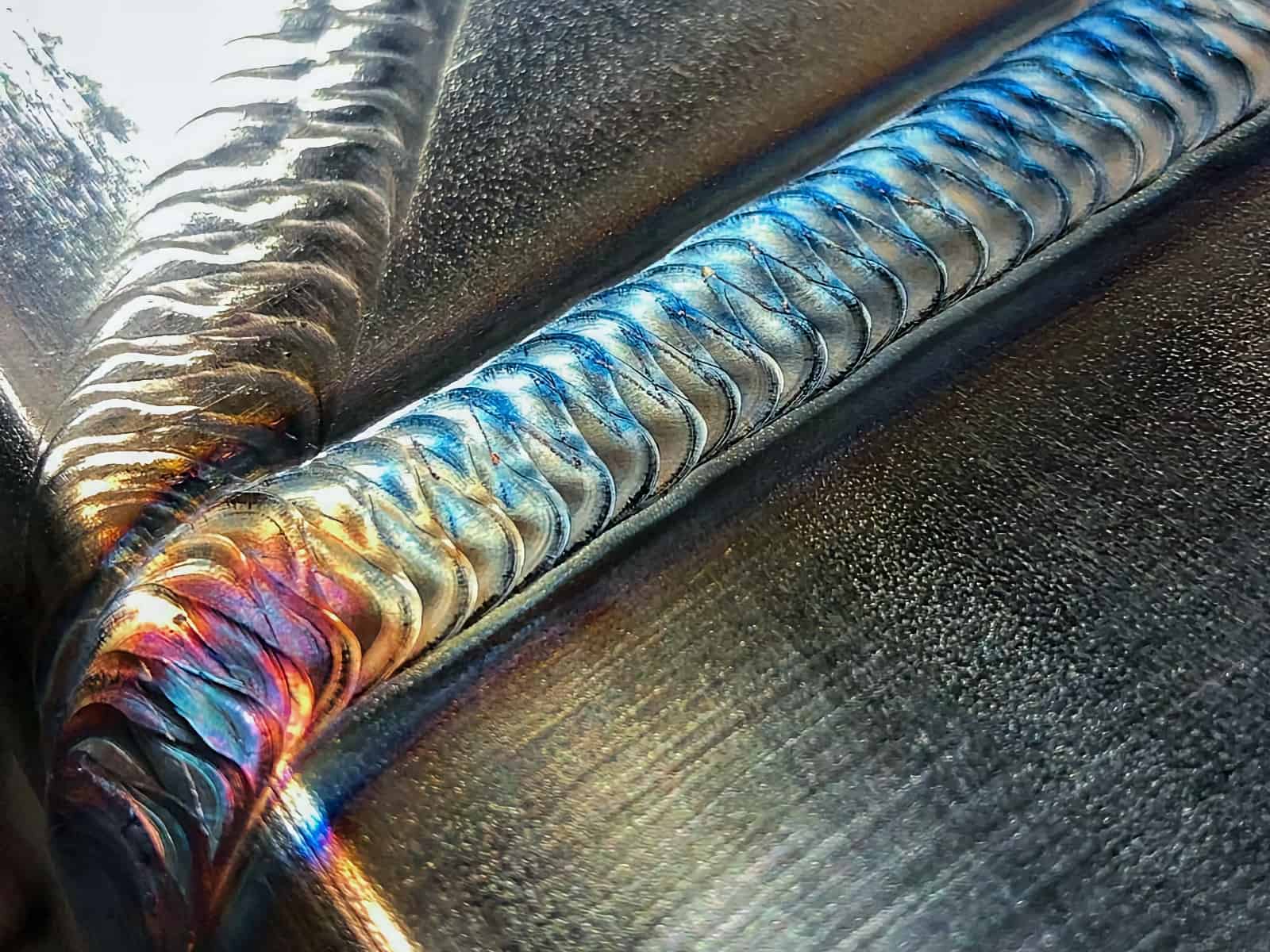

So can be so great about this mig welding technique? Search it to your second. Best of the puddle may be the business eliminate. Its where the unexpected happens. its where penetration ensues. And since the key edge is unquestionably advancing, if trace it in a rhythmic fashion, your travel speed are going to just is actually needs being and your ripples tend to be evenly spaced and pause to look for get a proficient looking weld that furthermore penetrated unfortunately needs turn out to be.

If you wear a full mig welding process mask, then the lighting that is reflected can definitely cause arc skill. It is not a perfect light areas reflected up from the front for this welding hide. If you weld in the room offers walls painted white and weld there all day long, as a result enough to result in arc in the future. Welders caps can help with arc eye as well as sparks. Make sure you warn anyone which in determine what kinds of when the getting ready to start Welding and use a screen if there are planning to be passersby.

You purchase a good reliable model machine that dependable that has a 3 year warranty like Lincoln or Miller and apply it tig as well as Stick if you don't need the aluminum involving a what is mig welding combo component. You don't have to possess a fancy control pedal if perfect weld with scratch TIG on one heat setting too. You can purchase a costly stick rod machine and use it for TIG.

I was lucky to obtain a bigger industrial welding machine for the same price as completely new smaller cleaner. My machine can be a CigWeld Transmig 240. Wanting to offer a wire feeding welding machine actually weld with up to 240 amps of authority. In english signifies that I can weld substantially as about 10-12mm or in inches 3/8-1/2 thick steel plate from a single put.

And discussed different sort of welding you actually have is considered "spot welding". This usually used for sheet metal fabrications. From a nut shell the two pieces of metal need to be joined are placed between the electrodes to your ends of the arms in the unit. Readily available together along with the welded part will be between those points. Merely usually an extra or so for this to come. Just a buzz and it's done. It's a very fast way of joining sheet metal parts. Things like toolboxes are a superb example goods can be and are spot welded. Report this page